Product Details:

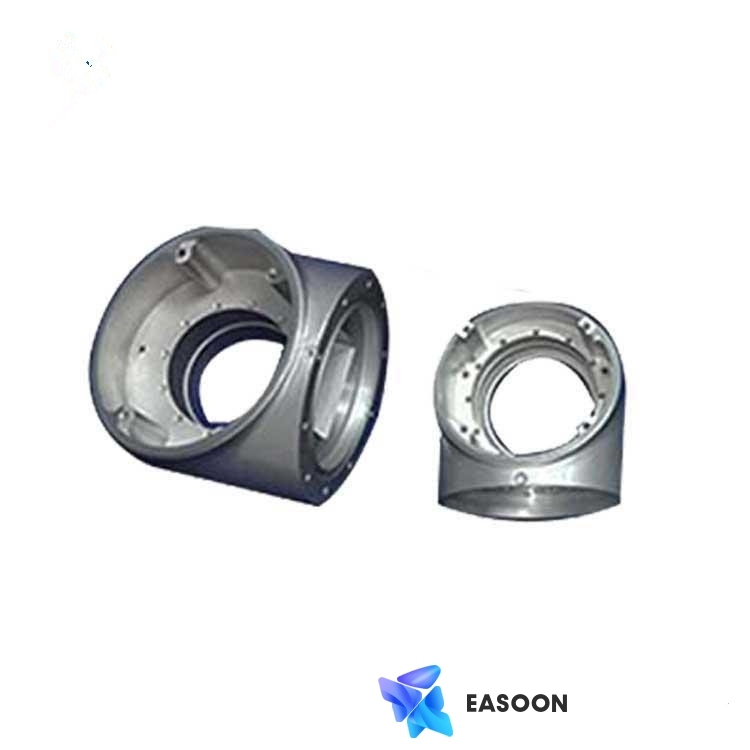

Custom Joint Components: At EasoonMade, we offer a vast selection of customized joint components that cater to various robot types and applications. Our expert team works closely with clients to design and produce parts that meet their specific requirements, ensuring seamless integration and enhanced operational performance.

High-Precision Manufacturing: EasoonMade leverages advanced manufacturing technologies and processes to produce robot parts with utmost precision. We utilize cutting-edge equipment and highly skilled technicians to ensure the highest level of accuracy and quality in every component we manufacture.

Materials and Durability: Our robot parts are made from top-quality materials that are carefully chosen for their rigidity, durability, and resistance to wear and tear. With our focus on longevity and reliability, we deliver components that can withstand the demands of various robotic applications.

Customization Options: EasoonMade understands that each robot has unique needs. Therefore, we offer a wide range of customization options, including size, shape, materials, and surface finishes. These customizable features ensure that our robot parts seamlessly integrate into different robotic systems and operate at optimal efficiency.

In the era of automation, customized robot parts serve as the driving force behind precision, flexibility, and performance. This article delves into the world of customized robot parts, shedding light on their advantages, applications, and the key factors involved in their successful implementation. By embracing the capabilities of precision engineering and adaptability, businesses can redefine the possibilities of automation, achieving unmatched productivity and efficiency.

Advantages of Customized Robot Parts:

Customized robot parts offer a host of advantages that transform the automation landscape. The ability to tailor these parts to specific requirements ensures a perfect fit, optimizing performance and reliability. With customizations, businesses can achieve higher levels of precision, reducing the margin for error commonly found in standard off-the-shelf components. Enhanced precision leads to improved product quality, increased operational efficiency, and higher customer satisfaction. Moreover, customized robot parts allow for seamless integration into existing systems, optimizing workflow and maximizing productivity.

Precision Engineering for Unmatched Performance:

Precision engineering forms the core of customized robot parts, enabling unparalleled performance and accuracy. Every component is meticulously designed and manufactured to meet tight tolerances, ensuring precise functionality and stability. Advanced manufacturing techniques such as CNC machining and 3D printing allow for the creation of complex shapes and intricate designs, enabling customized robot parts to fit seamlessly within specific automation processes. With precision engineering, businesses can unlock the full potential of their robotic systems, elevating performance to unprecedented levels.

Adaptability for Diverse Applications:

The adaptability of customized robot parts is a significant advantage in automation. These parts can be designed and modified to meet unique application requirements, accommodating various industries and tasks. From industrial manufacturing to healthcare, from agriculture to research and development, customized robot parts find invaluable applications across a range of sectors. With adaptability comes enhanced versatility, ensuring that automation systems can evolve and meet evolving needs, without the need for costly system overhauls.

Applications of Customized Robot Parts:

Customized robot parts have a wide range of applications, revolutionizing various industries. In automotive manufacturing, they optimize production lines, enabling precise assembly and streamlining operations. In the medical field, customized robot parts assist in surgical procedures, rehabilitation, and patient care. The electronics industry benefits from customized robot parts in intricate circuitry assembly and quality control processes. Moreover, research and development sectors leverage customized parts to explore new frontiers, test concepts, and redefine boundaries.

Considerations for Implementation:

Implementing customized robot parts requires careful consideration of several factors. Businesses must assess their unique automation needs and evaluate the compatibility of customized parts with existing systems. Cost-benefit analysis should be conducted to determine the return on investment associated with customization. Collaborating with experienced suppliers and integrators will ensure access to the latest advancements in technology and consistent support throughout the implementation process. Furthermore, prioritizing communication and collaboration between all stakeholders involved becomes vital for successful integration.

Conclusion:

Customized robot parts lay the foundation for precision, adaptability, and unparalleled performance in automation. By embracing the advantages of precision engineering and adaptability, businesses can unlock new levels of productivity, efficiency, and competitiveness. Customized robot parts cater to diverse applications and industries, enabling automation systems to evolve and meet unique challenges head-on. Adapt to the future of automation with customized robot parts and unleash the full potential of your operations.